Wiring

Contents

Wiring Techniques

This page will cover the different types of wiring practices to better help you decide on the best way to wire up your project.

Selecting Wire

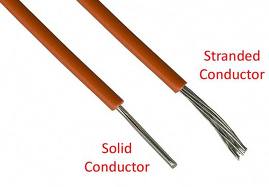

The size and type of wire used depends on the type of circuit it is being used in. Larger diameter wire is required for higher amperage circuits (A/C circuits of monitors and power supplies), whereas smaller diameter wire can be used in lower amperage circuits (control circuits). 22-24 gauge wire is a typical size used for wiring up control panels. 16-18 gauge wire is common for A/C power lines for things like power supplies and monitors. There are two basic types of wire: stranded and solid. Solid wire is more rigid and holds its shaped better than stranded wire. However, stranded wire is more flexible and easier to work with than solid wire.

Solid Wire

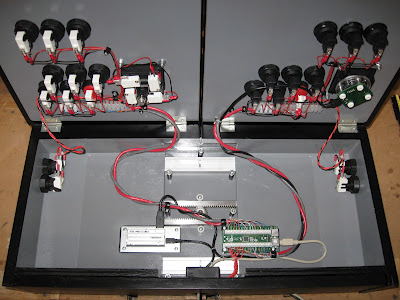

Typically, the only times you'll see solid wire being used in a project is when the builder uses CAT5 cable. Many people in this hobby come from computer backgrounds and use what they are familiar with, which is why some choose to use CAT5 cable for wiring their controls. They get multiple conductors in an easy to manage package. The wires inside the CAT5 cable are color coded which can make things a little easier when wiring up your controls. Here is a clean example, done by user TopJimmyCooks, of a CP wired using mainly CAT5 cable:

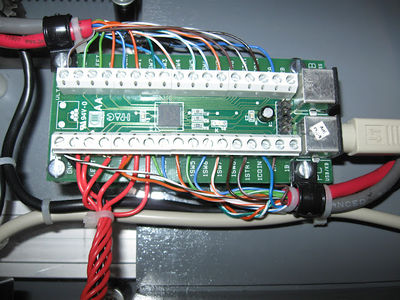

And a close up of his CAT5 wired to his interface of choice for this project, an I-PAC:

Stranded Wire

Wiring harnesses in original cabinets utilized stranded wire. Often called "hookup wire", it is readily available from auto parts stores and home improvement stores. Many builders choose to use stranded wire in their projects. Stranded wire is easier to crimp and solder than solid wire. Here is an example of an installed CP harness made with stranded wire:

Here is a power plug wired to a Molex connector, using 16 gauge stranded wire, to connect to a stock arcade machine power supply harness:

Connecting Wires

There is a vast variety of different types of connectors to choose from for wiring your project. While they all will work, some are better/safer to use than others. Sure, you can simply twist two wire ends together and tape the connection, but that is not very safe. The easiest safe way to connect wires is by using some type of connector. You can also solder wires together to create a strong, dependable connection.

Common Connectors

The most common way of connecting one wire to another is by using one of the following types of connectors. These connectors can be found at any hardware, auto parts, or home improvement store. They can come in either insulated or non-insulated varieties, but it is always wise to insulated connectors to reduce the likelyhood of unintentional short circuits.

Wire Nuts

Wire nuts are most commonly used in electrical systems of buildings. You will see them used to connect the building's wiring inside electrical boxes for lights, switches, and outlets. They mostly used with solid wire, but can be used with stranded as well. They make for a quick, reversable wire connection. No crimping tool is needed, only wire strippers. Typically not recommended for use in this hobby.

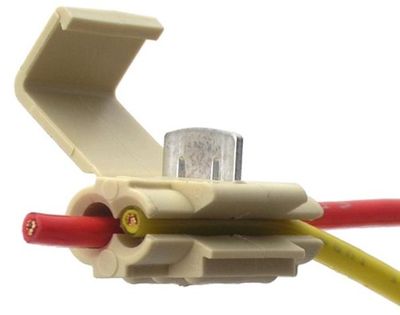

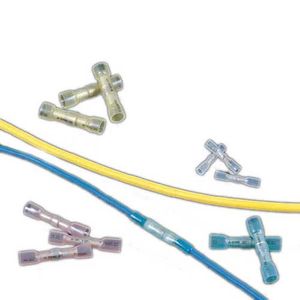

Scotch Locks

Scotch locks are the lazy man's connector of choice. No tools are required for the scotch lock. The scotch lock makes the connection between the wires by piercing the wires' insulation and wedging the conductors into the internal grooves of the scotch lock. Not recommended, they're ugly, and there's a better way.

Butt Splices

Butt splices connect one wire end to another wire end. The connection cannot be disconnected without cutting the butt splice out. They are handy for adding more length to a wire you find is too short. They are available in non-insulated, insulated, and heat shrink types. It is recommended that you used a heat shrink tube over a non-insulated butt splice.

Quick Disconnects

Coming soon...

Bullet Connectors

Coming soon...

Ring/Spade Terminals

Coming soon...

Specialty Connectors

Coming soon...